-

University Guide

University Guide

University Guide

INDEX- Introducing the President

- University Introduction

- University Evaluation

-

Policies and Initiatives

- Policy and Initiatives INDEX

- Compliance

- Crisis Management System

- Promoting gender equality

- International Exchange Policy

- Infrastructure longevity plan (individual construction plan)

- Environmental Initiatives

- Smoking is prohibited throughout the university grounds.

- Safety Management Action Plan

- JABEE Initiatives

- Basic rules regarding drinking among Muroran Institute of Technology students

- Policy for promoting the sharing of research facilities and equipment at Muroran Institute of Technology

- Campus Master Plan

- Muroran Institute of Technology Conflict of Interest Management Policy

- Digital Campus Promotion

- Muroran Institute of Technology Open Access Policy

- Muroran Institute of Technology Research Data Policy

-

Information Disclosure

- Information Disclosure INDEX

- Disclosure of corporate information (information about the organization)

- Disclosure of corporate information (information regarding business)

- Disclosure of corporate information (financial information)

- Publication of corporate information (evaluation information)

- Disclosure of corporate information (audit information)

- Publication of educational information

- Compliance status with the National University Corporation Governance Code

- Rules

- Information Disclosure System

- Personal Information Protection System

- Publication of guidelines for employees regarding the promotion of the elimination of discrimination against people with disabilities

- Announcement of the New Support System for Higher Education

- Application and recruitment information

- public relations

-

Faculty/Graduate School/Center etc.

Faculty/Graduate School/Center etc.

Faculty/Graduate School/Center etc.

INDEX- Faculty of Science and Engineering

- graduate school

-

Affiliated facilities (centers, etc.)

- Affiliated Facilities (Centers, etc.) INDEX

- Creative Collaboration Center

- Aerospace Plane Research Center

- Rare Earth Materials Research Center

- Computer Science Center

- Research Infrastructure Equipment Sharing Center

- Technology Department

- Career Support Center

- International Exchange Center

- Information Education Center

- Affiliated Library

- Health Management Center

- Gender Equality Promotion Office

- MONO Creation Future Co-Creation Organization

- Regional Collaboration Human Resources Development Center

- Manufacturing Infrastructure Center

- Robot Arena

- satellite

- Tokyo Office

- the study

-

Student Life/Employment

Student Life/Employment

Student Life/Employment

INDEX-

Courses and classes

- Course/Class INDEX

- Academic Calendar

- Lesson plan (syllabus)

- Classes (timetable)

- Exam (timetable)

- Course Affiliation

- Credit transfer with other universities

- Re-reading of course subjects

- CAMPUS SQUARE (Course registration)

- How to take the course

- Student Handbook/Graduate School Course Guidelines

- Transfer of departments, etc.

- Doctoral Degree Application Guide

- Academic Counseling and Guidance

- Duration of study

- Long-term student system

- Educational Programs (not required for graduation or completion)

- A Note About Generative AI

-

Student Life

- Student Life INDEX

- Suspension and Absence

- Various notification and certificate issuance procedures

- Student ID and student number

- Student discount card/school attendance certificate

- Procedures for taking a leave of absence, reinstating, and withdrawing from school

- New academic year orientation

- Preserving the on-site environment

- Attention students

- Transportation on and off campus

- Message board/contact method

- Harassment

- health care

- Events

- Welfare facilities

- Student Dormitory

- Student Support Center Introduction

- Student General Advice Office

- Extracurricular Activities

- Tuition, scholarships and other procedures

- Employment and qualification support

-

Courses and classes

-

Entrance Examination Information

Entrance Examination Information

Entrance Examination Information

INDEX- University Entrance Examination [Faculty]

- Graduate School Entrance Examination

- Transfer Admissions

- Entrance examination for international students

- Specialized students and research students

- Admission procedures, tuition fees, etc.

- FAQ

- University Introduction

- Request information

-

Social Cooperation

Social Cooperation

Social Cooperation

INDEX- Collaborative News

- Collaboration Centers, etc.

-

Industry-academia-government collaboration

- Industry-academia-government collaboration INDEX

- Alliance Lab

- Research Collaboration Association

- Muro Institute of Technology venture title

- Confidentiality

- Joint Research System

- Commissioned Research System

- Academic Guidance System

- Tangible research results

- Scholarship and Donation System

- Donation field etc.

- Future Creation Promotion Expenses

- Regarding the expenditure of personnel expenses of the principal investigator (PI) from direct costs of competitive research grants

- Research ethics and safety

- Public Lectures

- Muro Institute of Technology Science School

- University Visit

- Robot Soccer Contest

- Re-education for working adults

-

International Exchange

International Exchange

International Exchange

INDEX- International Academic Exchange Agreements

- Number of international students

- Researcher Database

- Entrance Exam

- Tuition Fees

- International Student Support (for new students)

-

Support for international students (for current students)

- Scholarships for International Students

- Japanese Language Course for International Students

- Immigration procedures (renewal of period of stay, permission to engage in activities other than those permitted under the status of residence, re-entry permission)

- Procedures after arriving in Japan

- Procedures for changing address (under construction)

- Procedures upon returning to Japan

- Notification of absence due to temporary return to Japan, travel, etc.

- Employment for international students

- Emergency Contact Information

- Studying abroad from Muro Institute of Technology

- Request for donations

-

University Guide

University Guide INDEX

- Introducing the President

- University Introduction

- University Evaluation

-

Policies and Initiatives

- Policy and Initiatives INDEX

- Compliance

- Crisis Management System

- Promoting gender equality

- International Exchange Policy

- Infrastructure longevity plan (individual construction plan)

- Environmental Initiatives

- Smoking is prohibited throughout the university grounds.

- Safety Management Action Plan

- JABEE Initiatives

- Basic rules regarding drinking among Muroran Institute of Technology students

- Policy for promoting the sharing of research facilities and equipment at Muroran Institute of Technology

- Campus Master Plan

- Muroran Institute of Technology Conflict of Interest Management Policy

- Digital Campus Promotion

- Muroran Institute of Technology Open Access Policy

- Muroran Institute of Technology Research Data Policy

-

Information Disclosure

- Information Disclosure INDEX

- Disclosure of corporate information (information about the organization)

- Disclosure of corporate information (information regarding business)

- Disclosure of corporate information (financial information)

- Publication of corporate information (evaluation information)

- Disclosure of corporate information (audit information)

- Publication of educational information

- Compliance status with the National University Corporation Governance Code

- Rules

- Information Disclosure System

- Personal Information Protection System

- Publication of guidelines for employees regarding the promotion of the elimination of discrimination against people with disabilities

- Announcement of the New Support System for Higher Education

- Application and recruitment information

- public relations

-

Faculty/Graduate School/Center etc.

Faculty/Graduate School/Center etc. INDEX

- Faculty of Science and Engineering

- graduate school

-

Affiliated facilities (centers, etc.)

- Affiliated Facilities (Centers, etc.) INDEX

- Creative Collaboration Center

- Aerospace Plane Research Center

- Rare Earth Materials Research Center

- Computer Science Center

- Research Infrastructure Equipment Sharing Center

- Technology Department

- Career Support Center

- International Exchange Center

- Information Education Center

- Affiliated Library

- Health Management Center

- Gender Equality Promotion Office

- MONO Creation Future Co-Creation Organization

- Regional Collaboration Human Resources Development Center

- Manufacturing Infrastructure Center

- Robot Arena

- satellite

- Tokyo Office

- the study

-

Student Life/Employment

Student Life/Employment INDEX

-

Courses and classes

- Course/Class INDEX

- Academic Calendar

- Lesson plan (syllabus)

- Classes (timetable)

- Exam (timetable)

- Course Affiliation

- Credit transfer with other universities

- Re-reading of course subjects

- CAMPUS SQUARE (Course registration)

- How to take the course

- Student Handbook/Graduate School Course Guidelines

- Transfer of departments, etc.

- Doctoral Degree Application Guide

- Academic Counseling and Guidance

- Duration of study

- Long-term student system

- Educational Programs (not required for graduation or completion)

- A Note About Generative AI

-

Student Life

- Student Life INDEX

- Suspension and Absence

- Various notification and certificate issuance procedures

- Student ID and student number

- Student discount card/school attendance certificate

- Procedures for taking a leave of absence, reinstating, and withdrawing from school

- New academic year orientation

- Preserving the on-site environment

- Attention students

- Transportation on and off campus

- Message board/contact method

- Harassment

- health care

- Events

- Welfare facilities

- Student Dormitory

- Student Support Center Introduction

- Student General Advice Office

- Extracurricular Activities

- Tuition, scholarships and other procedures

- Employment and qualification support

-

Courses and classes

- Entrance Examination Information

-

Social Cooperation

Social Collaboration INDEX

- Collaborative News

- Collaboration Centers, etc.

-

Industry-academia-government collaboration

- Industry-academia-government collaboration INDEX

- Alliance Lab

- Research Collaboration Association

- Muro Institute of Technology venture title

- Confidentiality

- Joint Research System

- Commissioned Research System

- Academic Guidance System

- Tangible research results

- Scholarship and Donation System

- Donation field etc.

- Future Creation Promotion Expenses

- Regarding the expenditure of personnel expenses of the principal investigator (PI) from direct costs of competitive research grants

- Research ethics and safety

- Public Lectures

- Muro Institute of Technology Science School

- University Visit

- Robot Soccer Contest

- Re-education for working adults

-

International Exchange

International Exchange Index

- International Academic Exchange Agreements

- Number of international students

- Researcher Database

- Entrance Exam

- Tuition Fees

- International Student Support (for new students)

-

Support for international students (for current students)

- Scholarships for International Students

- Japanese Language Course for International Students

- Immigration procedures (renewal of period of stay, permission to engage in activities other than those permitted under the status of residence, re-entry permission)

- Procedures after arriving in Japan

- Procedures for changing address (under construction)

- Procedures upon returning to Japan

- Notification of absence due to temporary return to Japan, travel, etc.

- Employment for international students

- Emergency Contact Information

- Studying abroad from Muro Institute of Technology

- Request for donations

- HOME

- Faculty/Graduate School/Center etc.

- Faculty of Science and Engineering

- Department of Creative Engineering

- Mechanical Engineering Course

Mechanical Engineering Course

I want to make machines that support the world! I want to learn the basics of machine building in a broad range of areas.

We provide education and research that covers everything from the fundamentals to applications of mechanical engineering, robotics, and aerospace engineering, including vehicles such as automobiles, trains, and aircraft, construction machinery such as bulldozers, the engines that power them, air conditioning and heating equipment, and the robots and industrial machinery that are responsible for production in factories.

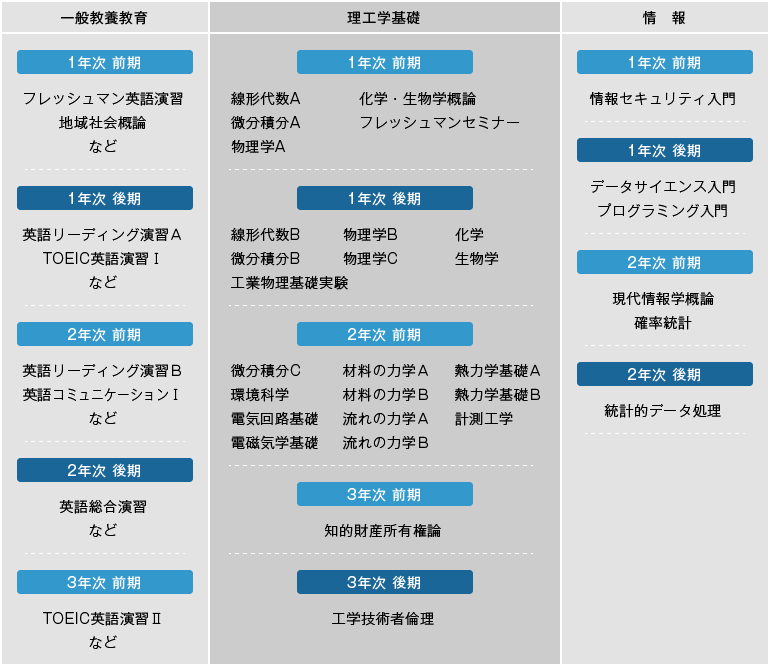

About the Education Program

A comprehensive curriculum that covers a wide range of subjects in mechanical engineering and related fields

From the first to the first half of the second year, students take general education subjects, faculty and department common subjects (natural sciences) and some information subjects to acquire communication skills and social literacy, as well as basic specialized subjects in related fields (electrical circuits, electromagnetism, measurement engineering, etc.) to develop a broad perspective. From the second half of the second year onwards, students in this course systematically study a specialized curriculum consisting of mechanical engineering and its related fields of robotics, aerospace engineering, electrical engineering and electronics, with a focus on dynamics, systems, engineering design and experiments.

Mechanical Engineering Course

Flow of the four years

First year

Students will develop the fundamentals of science and engineering by studying general education subjects such as "human and society-related subjects" and "foreign language subjects," common natural science subjects such as "mathematics," "physics," "chemistry," and "biology," and information-related subjects such as "Introduction to Information Security," "Introduction to Data Science," and "Introduction to Programming."

Second Year

In the first semester, students will study a range of subjects across fields, including "Basics of Electromagnetism," "Basics of Electrical Circuits," "Mechanics of Materials," "Mechanics of Flow," "Basics of Thermodynamics," and "Measurement Engineering," to improve their basic engineering skills. In addition, students will acquire data utilization skills through information subjects such as "Introduction to Modern Informatics," "Probability and Statistics," and "Statistical Data Processing." In the second semester, students will study basic course-specific subjects such as "Mechanical Mechanics," "Mechanics," "Electronic Circuits," and "Aerospace Structural Mechanics."

Third Year

From the second semester of the second year, students continue to study course-specific subjects. Students study compulsory subjects such as "Control Engineering," "Mechanical Drawing," and "Machine Work Practice," as well as elective subjects such as "Robotics," "Digital Circuits," and "Mechanical Materials Science," acquiring specialized knowledge that is the foundation of mechanical engineering and related fields, and acquiring applied skills through practical training and exercises.

Fourth Year

The main part of learning in the fourth year is practical, through graduation research. By applying the knowledge acquired up to that point to problems set in each field, students will make their knowledge essential and develop their problem-solving skills.

Mechanical Engineering Course Pickup

About the classes

Mechanical Engineering Experiment

In the mechanical engineering experiment, students conduct experiments related to various mechanical engineering themes (10 laboratories) to confirm the contents learned in class with their own hands and learn to apply the knowledge. One of these, the theme taught by the Materials Mechanics Laboratory, is "Measuring the material constants of metallic materials using strain gauges," and students measure the material constants of various commonly used metallic materials based on an understanding of strain (= deformation amount of solid) gauges and the variation and significant figures of experimental data.

About the Research

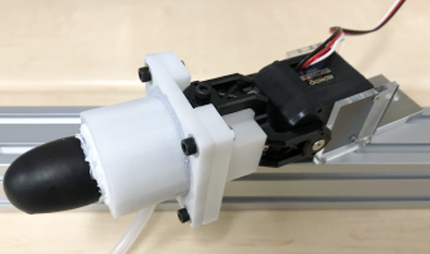

Research into next-generation robot technology and robot hands for a wide variety of tasks

Japan is a society with a declining population, and there is a shortage of workers to support the world. The use of robots and artificial intelligence is being considered as a way to compensate for this. Therefore, we are conducting research with the aim of developing robotics technology that will be useful for automation and labor saving. For example, next-generation robots will be required to work in collaboration with humans and in people's living spaces. We are researching robot hands that can perform a wide variety of tasks in such environments. As an example, the figure shows a robot finger with a multi-layer structure that uses fluids. A multi-layered finger makes it possible to easily hold a wide variety of objects. Aiming to further improve the functionality, we are working on improving the structure of each layer and adding tactile functions.

Assistant Professor Yoshitaka Fujihira

Research Field

Robot hand, object grasping/manipulation

Main research themes

Technology development for manipulating soft objects with robotic hands

Employment situation

- JFE Plant Engineering

- Hokkaido Railway Company

- Alps Electric

- Oki Electric Industry

- Kobelco Construction Machinery

- Nippon Steel Corporation

- Seiko Epson

- Taisei Corporation

- Narazaki Manufacturing Co., Ltd.

- Japan Steel Works, etc.